Glass double heads drilling machines offer a range of advantages that have transformed the way glass panels are drilled. These machines are designed to drill precise holes in glass panels quickly and efficiently, making them ideal for applications where accuracy and productivity are crucial. This article explores the various advantages of glass double heads drilling machines and their impact on the glass industry.

Increased Productivity

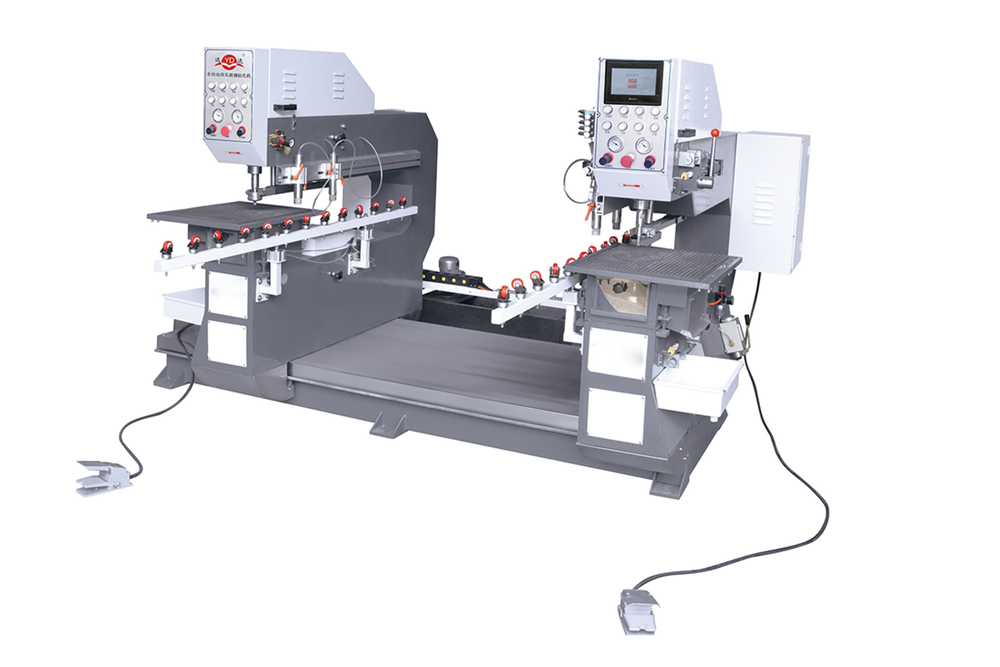

One of the primary advantages of glass double heads drilling machines is their ability to significantly increase productivity. These machines are equipped with two drilling heads, allowing them to drill two holes simultaneously. This dual-drilling capability allows manufacturers to drill more holes in less time, ultimately increasing the overall productivity of the glass processing operation.

Improved Efficiency

Glass double heads drilling machines are highly efficient, thanks to their dual-drilling capability. For example, LAD's glass double heads drilling machine, YD-DHD-1500MA, can drill two holes simultaneously, reducing the time required to complete each panel and enabling manufacturers to process more panels in less time. This increased efficiency can lead to cost savings and improved profitability for glass processing companies.

Precision Drilling

Precision is essential in glass processing, especially when drilling holes for hardware installation or other applications. Glass double heads drilling machines are designed to drill precise holes with high accuracy, ensuring that each hole is drilled to the exact specifications required. This precision is critical in applications where the integrity of the glass panel must be maintained, such as in architectural or automotive glass.

Versatility

Glass double heads drilling machines are versatile tools that can be used for a wide range of applications. These machines can drill holes of various sizes and shapes, making them suitable for a variety of projects. Whether drilling holes for shelf brackets, door handles, or decorative purposes, glass double heads drilling machines can handle the task with ease.

Cost-Effectiveness

While the initial cost of purchasing a glass double heads drilling machine may be higher than that of a single-head drilling machine, the long-term cost savings can be significant. The increased productivity and efficiency of these machines can lead to lower production costs per panel, ultimately saving manufacturers money in the long run.

Reduced Labor Costs

Glass double heads drilling machines require less labor to operate compared to single-head drilling machines. With two drilling heads, these machines can drill twice as many holes in the same amount of time, reducing the need for additional labor. This can result in significant cost savings for glass processing companies, especially for larger-scale operations.

Improved Safety

Glass double heads drilling machines are equipped with safety features to protect operators and prevent accidents. These features may include automatic shut-off systems, protective guards around moving parts, and emergency stop buttons. Additionally, some machines are equipped with sensors that can detect when an operator is too close to the machine and automatically stop it to prevent injury.

Enhanced Flexibility

Glass double heads drilling machines offer enhanced flexibility in terms of hole placement and spacing. With two drilling heads, operators have more options for positioning holes on glass panels, allowing for greater flexibility in design and layout. This flexibility can be especially useful in architectural applications where custom hole placements are required.

In conclusion, glass double heads drilling machines offer a range of advantages that have transformed the way glass panels are drilled in the glass processing industry. As technology continues to advance, we can expect to see further innovations in glass double heads drilling machines that will further improve their capabilities and benefits for manufacturers in the glass industry.