CNC (Computer Numerical Control) glass cutting machines have revolutionized the glass industry by offering unparalleled precision, efficiency, and versatility in cutting glass. These machines use computer-controlled systems to guide the cutting tools along the desired path, allowing for highly accurate and complex cuts that were once difficult or impossible to achieve with traditional methods. This article explores the numerous benefits of CNC glass cutting machines for precision work in various industries.

Superior Precision and Accuracy

One of the primary advantages of CNC glass cutting machines is their ability to achieve extremely high levels of precision and accuracy. The computer-controlled systems can guide the cutting tools to within fractions of a millimeter, ensuring that even the most intricate designs and patterns are cut with exacting detail. This level of precision is essential for industries such as electronics, where glass components must fit together perfectly to ensure proper functionality.

Increased Efficiency and Productivity

CNC glass cutting machines are significantly more efficient than traditional manual cutting methods. These machines can work continuously, cutting multiple pieces of glass with consistent precision and speed. This increased efficiency translates into higher productivity, allowing manufacturers to produce more glass products in less time.

Versatility in Cutting Options

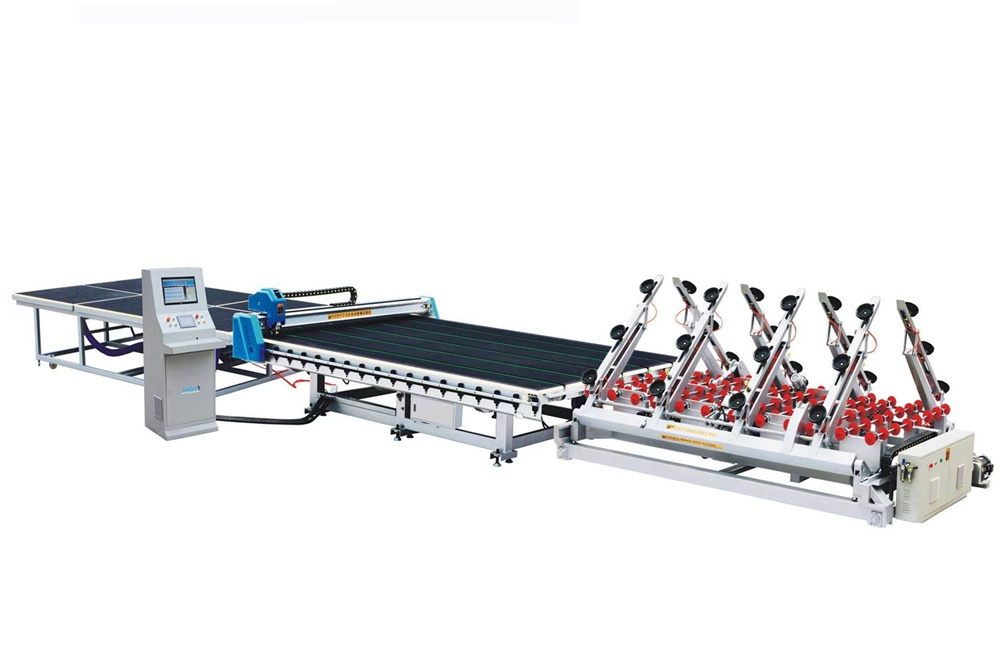

For instance, LAD's CNC glass cutting machine production line offers a wide range of cutting options, allowing manufacturers to create complex shapes and designs with ease. These machines can cut straight lines, curves, angles, and even intricate patterns, opening up a world of design possibilities for architects, artists, and designers. Additionally, CNC machines can cut glass of various thicknesses, making them suitable for a wide range of applications.

Reduced Material Waste

The precision of CNC glass cutting machines helps reduce material waste significantly. By cutting glass with minimal kerf (the width of the cut), these machines maximize the amount of usable glass from each sheet, reducing the overall cost of production. This is especially important for expensive specialty glass or when working with limited quantities of glass.

Improved Safety and Ergonomics

CNC glass cutting machines improve safety in the workplace by reducing the need for manual cutting methods. Manual glass cutting can be dangerous, as it requires the operator to handle sharp tools and glass shards. CNC machines eliminate these risks by automating the cutting process, ensuring that operators are not exposed to potential hazards.

Enhanced Quality Control

CNC glass cutting machines offer superior quality control compared to manual cutting methods. The computer-controlled systems can be programmed to perform precise measurements and cuts, ensuring that each piece of glass meets the required specifications. This level of quality control is essential for industries such as automotive and aerospace, where precision is critical.

Cost-Effectiveness

While CNC glass cutting machines may have a higher initial cost compared to traditional cutting methods, they offer significant cost savings in the long run. The efficiency and precision of these machines reduce labor costs and material waste, ultimately lowering the overall cost of production. Additionally, the versatility of CNC machines allows manufacturers to offer a wider range of products, potentially increasing revenue and profitability.

Applications of CNC Glass Cutting Machines

CNC glass cutting machines are used in a variety of industries and applications, including:

Automotive: CNC machines are used to cut glass for automotive windows, windshields, and sunroofs with precise dimensions to ensure a perfect fit.

Architecture: CNC machines are used to create intricate glass facades, walls, and windows in modern buildings, adding a touch of elegance and sophistication to architectural designs.

Electronics: CNC machines are used to cut glass for electronic displays, touchscreens, and solar panels with precise dimensions and shapes to ensure proper functionality.

Art and Design: CNC machines are used by artists and designers to create custom glass artwork, sculptures, and installations with intricate designs and patterns.

Conclusion

CNC glass cutting machines have revolutionized the glass industry by offering superior precision, efficiency, and versatility in cutting glass. These machines are essential for industries that require precise glass components, such as electronics, architecture, and automotive. The benefits of CNC glass cutting machines, including increased efficiency, reduced material waste, and enhanced safety, make them an invaluable tool for manufacturers and designers seeking to achieve the highest levels of precision and quality in their glass products.